The Review of Manufacturing Technology for Aircraft Structural Part

2020-05-14

Abstract

This paper presents the digital design and manufacturing technology for aircraft structural parts since the aircraft structural parts is becoming large-scale, integrated and complicated, and the requirement of manufacturing accuracy is higher, which taking challenge for manufacturing technology. The application of digital technology and intelligent technology in the process of aircraft structure part manufacture, and building the design and manufacturing collaborative platform for aircraft structure part to realization high efficiency, high quality, low cost, environmental protection and flexible design and manufacturing of aircraft structural parts is of great significance to improve the enterprise core competitiveness.

1. Introduction

As a typical representative of the equipment manufacturing industry, The Aviation manufacturing industry is a strategic high-tech industry which reflecting a country's overall national strength and the overall industrial level. It’s also one of the ten major areas of China's manufacturing 2025. High efficiency and high quality is an important condition for design and manufacturing of aircraft structural parts to ensure the performance and progress of aircraft manufacturing. It is not only requiring the application of the combination of digital technology to aircraft structure design and manufacturing process simply, but also more emphasis on collaborative of design and manufacturing, namely product goals would be set to a driver, the real-time, decentralized design information and manufacturing information will be collecting, optimization and integration by intelligent control system, to better service in product design and manufacturing processes. In order to better service in the whole process of design and manufacturing of products. Therefore, how to fuse the design process and manufacturing process of aircraft structural parts and build the design and manufacturing system of aircraft structural parts based on intelligent technology is the urgent demand of the equipment manufacturing industry in our country.

For the first time, the fourth industrial revolution (industry 4.0) which is dominated by intelligent manufacturing is put forward since 2011 in the German Hanover Fair, other countries also put forward the corresponding development plan for intelligent manufacturing, such as the United States to revitalize manufacturing strategy, Japanese manufacturing white paper and made in China 2025.Visible intelligent manufacturing is becoming a new round of industrial competition in the high ground. The world is highly valued. Aircraft structural parts is a typical production mode of small batch and multi variety, which is not conducive to the accumulation and reuse for knowledge. Therefore, it is of great and practical significance to apply intelligent technology in the design and manufacture process of aircraft structural parts.

2. Research status

The American Lockheed Martin in the JSF project used the product lifecycle management (PLM) software as integration platform and restructured company process by application the digital design and manufacturing management and give full play to the partner's optimal ability. The JSF aircraft design time reduced by 50%, 66% reduction in manufacturing time, assembly tooling reduced 90%, discrete parts are reduced by 50%. The design and manufacturing and maintenance costs are reduced by 50%. Boeing company in the new generation of war space vehicle, through the application of MBD/MBI (model based define and model based operating instructions) reduced assembly time 57%, and realization of the following technical breakthrough: design 3d transition to 3D manufacturing data technology, 3D product and process information transmitted to the manufacturing unit workers, the digital data of manufacturing operations at the scene can be acquisition and feedback, and the management of digital quality data and compliance document.

Domestic aviation manufacturing enterprises keep up with the world advanced aeronautical manufacturing technology and development of enterprises, through sustained investment in recent years, has been realization of the digital design of the

product and manufacturing process based on the model, the key parts manufacturing has basically achieved the machining process of NC. Domestic advanced aeronautical manufacturing enterprise has initially built digital workshop environment, developed a series of business system and software tools, to achieve the digital control of the manufacturing process. Local level has been basically close to international aviation manufacturing enterprises in the advanced level, having from digital to the automation and intelligent manufacturing development foundation. But compared with foreign advanced level and from the technology development trend, the existing aircraft structure parts processing workshop is still in primary stage in integration and flexibility and intelligence which mainly relying on advanced and automation of single equipment to realization the efficient manufacturing of aircraft structural parts.

3. Design technology of aircraft structural parts for manufacturing

The full three-dimensional design technology based on the MBD has been gradually applied to change the aircraft product development methods to shorten the development cycle of aircraft products in the domestic aircraft design process. However, the design process of aircraft structural part is focusing on functionality and lacking of consideration of its manufacturing process which leading to the design process and manufacturing process fracture and increasing the difficulty of manufacturing and production costs. Moreover, aircraft structural parts are a typical production mode of small batch and multi variety which is difficult to accumulate and reuse the knowledge by a large number of production mode, Therefore, the establishment of aircraft structural part design and manufacturing knowledge acquisition, reuse and integration technology, in order to break the information barrier between design and manufacture. We need to consider the manufacturability in the design process of aircraft structure parts to realization manufacturing oriented intelligent design. The core of manufacturing oriented design lies on knowledge acquisition, expression and modeling technology.

3.1. Acquisition and expression of manufacturing process knowledge

The processing technology of aircraft structural parts is complicated. How to acquire and express the machining process knowledge of aircraft structural parts accurately and completely to promote the intelligence of design process for aircraft structural parts is important. Although the machining process knowledge of aircraft structural parts is complex and various. But the vast number of process knowledge is related to the Features of the parts. Feature technology plays an important role in information integration as a means of digital manufacturing. In the application of traditional research and commercial software, feature technology has been widely used in the field of CAD/CAM. Especially it has been widely accepted in the field of CAM, which being considered that can effectively improve the process of programming efficiency, conducive to the integration and sharing of knowledge and improving the manufacturing efficiency and quality of the parts and so on.But how to make the feature technology as the link between the design process and manufacturing process is worth discussing and focusing on. Feature is a group geometry with specific attributes and interrelation which including a general description of the parts shape, process and function information.

It is the best carrier to integrate information of design and manufacturing which can effectively improve product design automation. Features can transfer information to the downstream manufacturing process and communicate design process and the manufacturing process as the link. Through the establishment process knowledge acquisition and representation model based on the feature, we can build the features knowledge base for the design process to achieve sharing knowledge in the design and manufacturing process, which provides the basis for manufacturing oriented intelligent design.

3.2. Parametric design of 3D model based on feature

The aircraft is a variety of high-tech integrated body which representing the level of a national industrial design and manufacturing and assembly. With the slowdown of the global economy, the development of manufacturing industry into a difficult period. The enterprises need to change the traditional mode that focused on the production task and do not pay attention to the production cost control. Especially in aircraft structural parts, the material cost is high. And the machining process is long. Unreasonable design is very easy to cause the quality of the products is difficult to control, which increasing the difficulty of product manufacturing and production costs. Therefore, it need to build the fast, high-quality design methods for aircraft structural parts urgently to enhance the core competitiveness of the aircraft manufacturing industry.Although the exterior structure of the aircraft structural part is complex. But the feature technology in the design and manufacturing process is widely used. The feature types of aircraft structural parts can be divided into slot feature, rib feature, hole feature and contour feature, which we define as geometry features. Aircraft structural parts not only need to define the part geometry in the design process. But also need to define parameter information including the technology of parts and material and precision and so on in the design process, which we will define as process features, it is an important basis for the machining and inspection. In the design process of aircraft structure parts, the feature based parametric modeling

technology and the process knowledge interpreter based on feature which combined with the full 3D modeling idea based on MBD is application in the building of the parts’ geometric and the marking of process feature, which making machining process knowledge integrated into the aircraft structure parts fully. The design process become the manufacturing process and it realize the intelligent design of aircraft structural parts.

4. Key technology of high efficiency digital processing for aircraft structural parts

Modern aircraft structural parts using a large number of integrated design mode. Its structure is complex and the types of features is variety which leading to manufacturing is more difficult. The aircraft structural parts achieve digital manufacturing process after years of technical research and application. But compared with foreign advanced technology, there are still the following problems. The NC programming cycle of large aircraft structural part is long, and the quality of

programming is low. In the processing, it is easy to produce deformation. The deformation control is difficult. And the processing efficiency is not high. It is difficult to control the quality of the parts. In short, the processing of aircraft structural parts is still dependent on personnel experience. In the process still needs continuous manual intervention and control which hindering the implementation of automation. Therefore, it is important to develop the research of the automatic and intelligent machining technology in the manufacturing process of aircraft structural parts and realize the flexible manufacture of aircraft structural parts which has great significance to improve the technical level of aircraft manufacturing industry.

4.1. Integrated process programming platform

The efficiency and quality of aircraft structural parts process programming has become one of the major bottlenecks in the manufacturing process cycle of aircraft structural parts. Ying Guang Li et al proposed user custom machining feature modeling method oriented complex aircraft structure parts and machining feature recognition technology based on holistic attribute adjacency graph. Meanwhile, they developed a intelligent programming system based on feature which realization the intelligent programming of complex aircraft structure parts. The system can achieve automatic recognition of machining features for aircraft structure parts and aircraft structure piece machining process planning and NC program compiling automatically with process knowledge database, cutting parameter database and the manufacturing resource database platform, which providing complete solutions for aircraft structural parts programming process. The recognition rate of the typical features is as high as 95%, and the programming efficiency is increased by more than 3 times. With the expansion of the system functions, the system will become an integrated platform, including process examination, feature recognition and process planning, tool path generation, post processing, simulation and optimizing for the whole programming process of aircraft structural parts. Meanwhile, with the continuous improvement and perfection of process knowledge database, cutting parameter database and manufacturing resource database, the future aircraft structural parts programming tasks will be completed all by computer. The Engineer will also be liberated from the arduous process programming tasks, to carry out process technology researching and process knowledge maintenance and updating.

4.2. Automatic performance evaluation and security technology of NC equipment

NC machine tool is known as the industry’s Mother Machine tools. It’s performance and operation status will direct impact on aircraft structure parts processing quality and processing time. Especially under the request of without manual intervention, the accuracy and performance and failure of the machine tool real-time prediction assessment and analysis and processing put forward higher requirements. The accuracy of the machine tool is an important guarantee for the machining quality of aircraft structural parts. Traditional machine tool accuracy assessment method has the following problems: firstly, the detection time is long. It need to analyze a large number of data. Secondly, it is unable to achieve the real-time online compensation for the precision of the machine tool which need artificial intervention. Germany DST machine tool companies developed a set of machine tool accuracy computer-aided diagnosis system (SQS). The system can automatic detect and compensate the machine tool's accuracy in space and five axis linkage precision fast and calculate andassess of spatial accuracy after the compensation by running a set of predefined standard test procedures. It is mainly through the optical principle to detect the spatial error and R-TEST to detect the attitude error of the rotating head. This machine tool precision automation system developed by DST can complete the automatic detection and compensation of the precision of the machine in 30 minutes. In the intelligent manufacturing plant, it achieves real-time tracking the accuracy of the machine tool. To integrate with the information system of the workshop, we can update the manufacturing resource database in time and provide the selection basis of the machine tool in the manufacturing process of aircraft structure parts.

CNC machine tool itself is a very complex system. If it can predict the failure of machine tools and pre maintain in timely which will greatly improve the utilization Rate of machine tools. Integration and fusion in depth of advanced manufacturing technology and information technology and intelligent technology in digital workshop environment achieve intelligent prediction and maintenance of machine tools. Through a sensor network system realizes real-time acquisition of vibration and current and noise and signal of electrical and mechanical features of machine tool equipment. And achieve their state and environment of self-perception. The sensing signal is transmitted to the control system by industrial Ethernet. According to the received signal, the control system gives the early warning and decision making for the key functional components’ health status based on the neural network and other inference algorithms with the support of expert knowledge base. After receiving the decision information, the machine tool adjusts its own operation mode adaptively or maintain by maintenance engineer to reduce product quality accidents and lockout caused by the failure of machine tools.

4.3. Adaptive control technology for machining process

The machining quality and machining efficiency of aircraft structural parts is not only related to machine tools and NC code. But also related to the tools and fixture and measurement and deformation control technology and so on. The adaptive clamping fixture and real-time machining process monitoring and machining and measurement integration technology will be an important part of intelligent flexible production line in the future intelligent machining plants.With the real-time monitoring of the cutting force and the rigid of the part based on in process feature, the adaptive fixture can adjust the fix state and force to match the workpiece and the cutting force to prevent the deformation of the workpiece.

At the same time, in order to adapt to the flexible production without artificial intervention mode, the parts were classified family according to the structure characteristics of the aircraft structure. Meanwhile, considering the characteristic of manufacturing process and structure size, the standard quick fixture model is used to realize parts with different specifications and the special fixture machining on different machine tools, in order to adapt to automated production mode of aircraft structural parts in the digital workshop.

At present, foreign countries have developed many sets of commercial monitoring software. But machining state recognition only based on monitoring signal. The machining process of complex aircraft structural parts is susceptible to the effects of fluctuations of the machining state which generating frequent false alarms that affect the normal production. Therefore, we need to make in-depth research on the remote

monitoring and control of CNC system technology. The spindle cutting power will be real-time monitor to recognize machining state combined with process information. Once found abnormal machining state, it should be control machine tool stop machining immediately to prevent parts quality problem caused by tool wear and breakage and tool path error and so on to enhance recognition accuracy of machining status.

Machining and measurement integration technology is mainly used in the parts clamping processing or complete one or some steps machining. The spatial location and feature size of the part were measured with the detection system built-in machine. Then readjust the machine coordinate system and NC code of parts for further machining according to the error distribution by analysis of the measurement data to ensure the dimension requirements of design. The machining quality of the parts in the flexible production line is guaranteed, and the machining error caused by these factors such as the parts loading and clamping and the positioning of tools and parts and the deformation of the parts are reduced.

4.4. Intelligent production management and control in manufacturing process

Intelligent production management and control center will be the brain of aircraft structural parts machining plant in the future which realization the data collection, analysis, decision making and other functions in one set and responsible for the unified allocation and management of all the resources in the plant. The aircraft structural parts CNC manufacturing process control, job scheduling, on-site management and manufacturing resource management is achieving with the support of digital production management system. On this basis, a virtual factory which real time operation with the actual factory workshop should be built. The production scheduling need be simulated in the virtual plant in order to determine the effectiveness of the scheduling. At the same time, the actual plant operation data is transmitted to the intelligent production control center to drive the virtual factory operation. Intelligent production control center will do decision-making according to the feedback data that the virtual factory simulating to achieve the actual factory scheduling control. The intelligent production management and control center effectively extends the function of the human brain, and has a great effect on the realization the without manual intervention or less manual intervention manufacturing of the aircraft structural parts.

5. Collaborative platform for design and manufacture of aircraft structural parts

Modern aircraft research and development are general using of multi manufacturer and remote collaborative development model. The production mode of small batch and multi variety of aircraft structural parts. Especially in the development and production process is accompanied by a large number of design changes which required manufacturing process to respond quickly, including manufacturer selection, process and resource preparation and so on. At the same time, in the traditional aircraft structure development process, the design process and manufacturing process is relatively independent, which only has the design to manufacture data transmission in one-way. The manufacturing process data cannot be feedback to design department. Therefore, to establish the multi information communication channels of the aircraft structural parts’ design and manufacturing process based on digital technology and construction the collaborative platform of design and manufacturing for aircraft structural part achieve the aircraft structure life cycle data sharing of multi sectoral and area, in order to truly realization collaborative design and collaborative manufacturing and design and manufacture collaboration.

From the overall objective of collaborative research and development, the product digital collaborative development has two models. It is the horizontal (multidisciplinary collaborative development MDO) and vertical (product life cycle of collaborative) respectively. Airbus applied collaborative technology research in Viva Ce (value improvement through a virtual aeronautical collaborative enterprise) system research project from feasibility study and concept design until the detailed design of the entire life cycle, and constructs a multidisciplinary collaborative development system framework of MDO. It applied in three aviation of helicopter, aircraft and engine. In the process of the Airbus A380 development, the idea of multi subject cooperative development is fully utilized in the design of the aircraft. But these digital collaborative development methods are just to achieve the data from upstream to downstream in one-way or horizontal transmission between the same level and lack of downstream data to the upstream feedback.

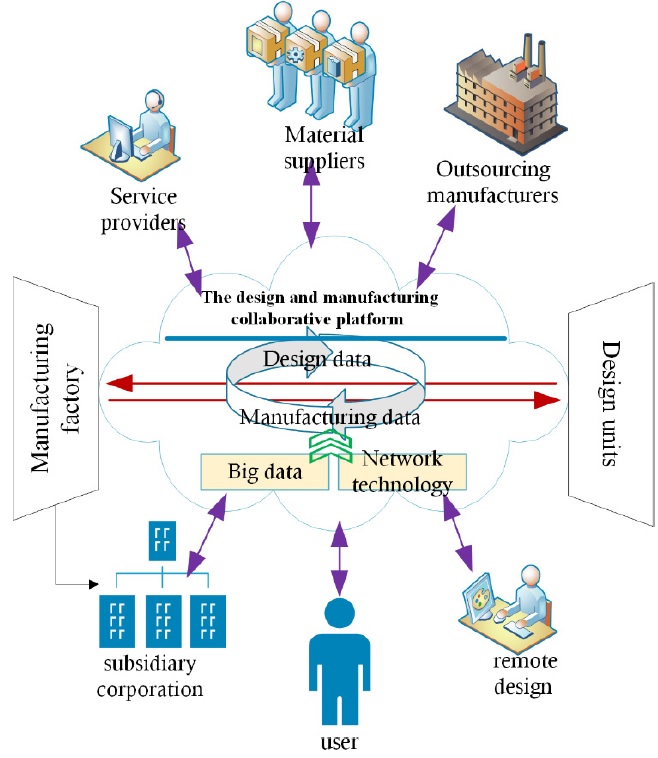

Figure 1 The design and manufacturing collaborative platform for aircraft structure part

The development of big data technology and network technology provides the basic conditions for construction of the collaborative platform. In the collaborative platform, the software resources (CAD, CAE software), hardware resources (numerical control equipment, testing equipment, etc.) and knowledge resources (process knowledge database, parameter database) that belong to different levels, different regions and design departments and different regional manufacturer can achieve horizontal and vertical sharing. The direct transmission of intelligent coordination and scheduling data of the design and manufacture process can complete aircraft structure design and manufacturing process fast to achieve synchronization of distributed resources. At the same time, aircraft structural parts manufacturing process data can rapidly and timely feedback to the design department by collaborative platform to guidance and optimization the design process of aircraft structural parts which could enhance aircraft structure parts manufacturability and reduce the aircraft structure parts and aircraft product development cycle. Fig. 1 shows the collaborative platform architecture for aircraft structural design and manufacturing.

Acknowledgements

The application of digital technology in the design and manufacture of aircraft structure parts effectively improve the processing quality and processing efficiency of aircraft structural parts, but aircraft structural parts is a small batch and multi variety production mode which not only need to enhance the quality and efficiency, more need to enhance the flexibility and automation. Future aircraft structural parts design and manufacture should gradually to the intelligent development, breaking the traditional thought of design and manufacturing process is separation, building aircraft structure parts design and manufacture collaborative platform, realization of flexible automatic produce for aircraft structural parts with high efficiency and high quality. But the intelligent manufacturing needs to be based on highly integrated automation production, the domestic aviation enterprise is still a large gap from this requirement. It is imperative to carry out the related key technology research for aircraft structure parts smart design and manufacturing, and promoting the application of the related technologies and standards, to achieve intelligent manufacturing landing in the aircraft structure design and manufacturing field. The authors gratefully acknowledge National Science and Technology Major Project (2013ZX04001-021).