According to machining requirements, we will recommend the cutting tools according to the following recommendations:

2020-03-09

According to machining requirements, we will recommend the cutting tools according to the following recommendations:

1. To understand the basic material, characteristics, conditions, manufacturing process of the work piece being cut ...

For example: whether the customer needs the work piece to reach the mirror surface (or the level of the mirror surface), the work piece size, tolerance value, the work piece corner can’t have cutting tool joint points, NC program cutting paths, customer work piece application and other related issues, in order Select the applicable cutting tool.

2. Firstly, we need to understand what is the difference between cutting tools of different materials (example: difference in strength and hardness ...)

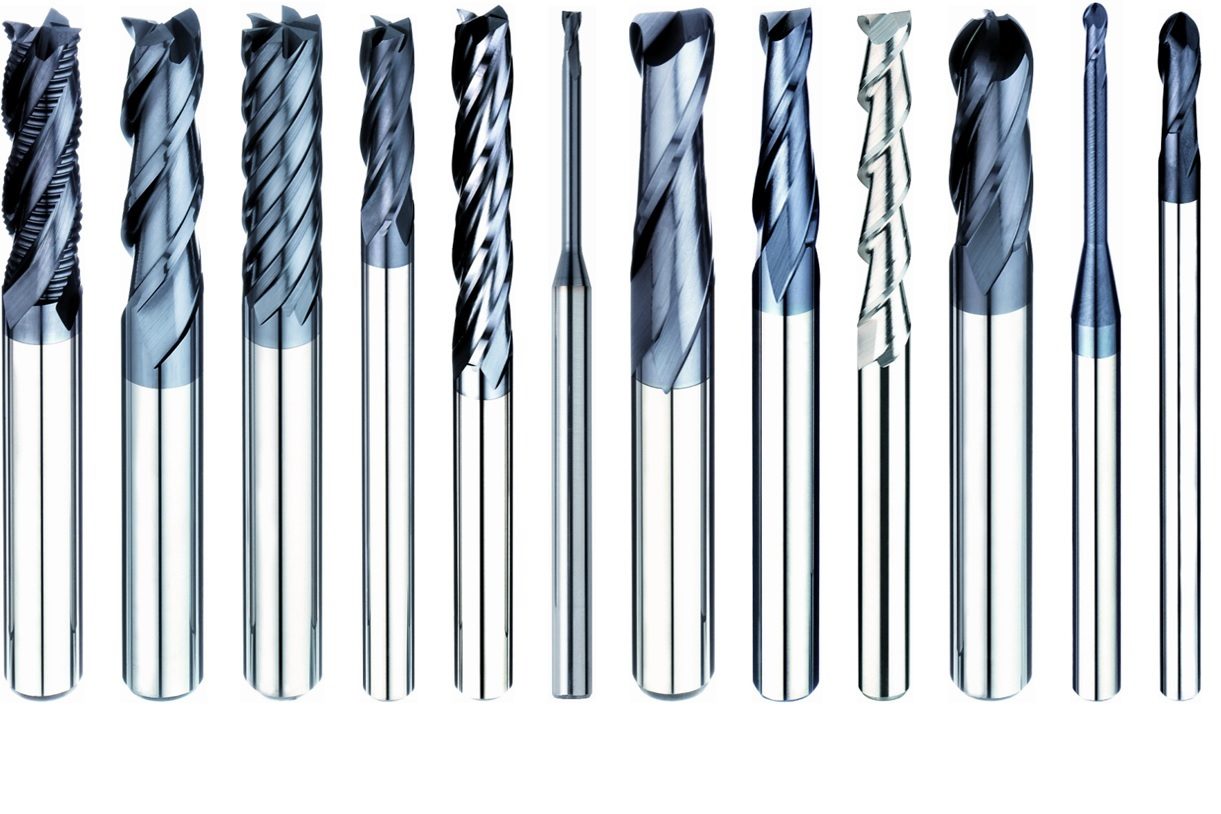

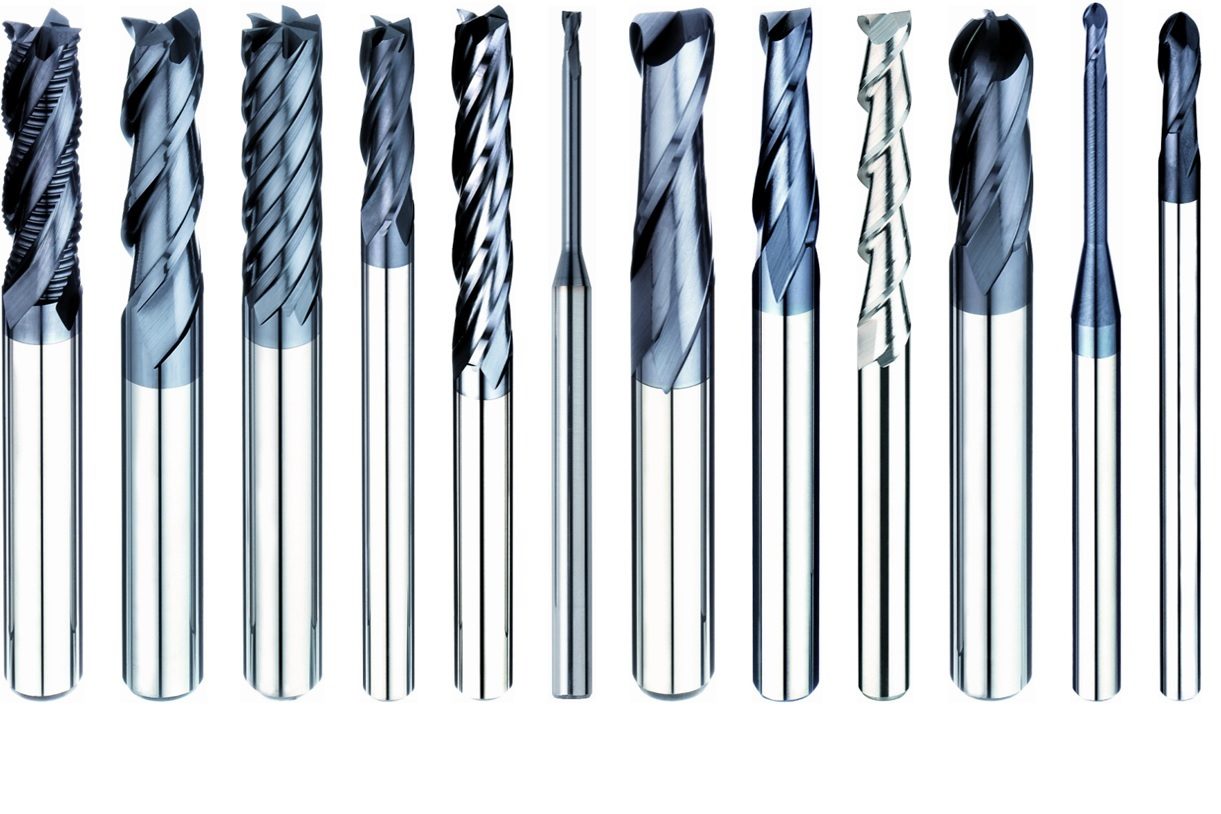

At present, all milling cutters are roughly classified into: single crystal diamond cutters, PCD CO diamond cutters, PCD Si diamond cutters, PCBN cutters, cermet cutters, tungsten carbide cutting tools, HSS cutters, ordinary steel cutters, and then according to the cutting work pieces pick the right cutting tool.

3. Select cutting tools according to the special requirements of the work piece (eg, the work piece has a deep groove surface ...)

Generally, you can choose the shape of the end mill types according to the relevant conditions of the work piece, the surface stretch, the surface rotation, the surface ball, the fillet shape, the conical cylindrical shape, and other related conditions. It is divided into standard type, long neck type and tapered neck type, which can be selected according to the processing depth, shape and appearance of the work piece, three-dimensional milling path, medium and fine milling of the processed object, and other related conditions. The interference angle should be considered when choosing between the two options. Compared with the long-neck type, the tapered-neck end mill has higher rigidity, which can improve cutting conditions and achieve better machining accuracy. You should try to choose a tapered-neck type Milling cutter.

4. Selecting end mills with different ball nose accuracy and smooth cutting edges according to the machining accuracy and the surface fineness of the work piece.

The arc accuracy of ball end mills is usually ± 5μm, but there are also high precision endmills of ± 2 ~ 3μm, which can be used for high precision machining.

5. Selecting the tool coating according to the type and hardness of the work piece.

For example, when processing work pieces with hardness below HRC40, such as carbon steel, WOTEK TiALN coating can be used. When work pieces with hardness around HRC50, such as alloy steel S, tool steel, etc., can choose nano aluminum nitride -NanoTiAlN coating. For workpieces with higher working hardness, the tool shape, hard alloy material, and coating are all WOTEK TiALN + PLC coatings for high-hardness processing dedicated to processing high-hardness materials.

6. When the work piece is difficult to cut, special high-hardness tools of special materials (such as cermet and diamond tools) are required.

For example: When cutting metal composite materials, because the material is high-nickel, it is best to use WOTEK cermet tools or PCBN diamond tools to solve difficult cutting problems.