CNC Cutting Tool Innovative Solutions: Technical Breakthrough in Precision Machining

2024-12-03

CNC Cutting Tool Innovative Solutions: Technical Breakthrough in Precision Machining

Project Background

In modern industrial manufacturing, precision CNC cutting tools are key to improving production efficiency and product quality. This case study details how we provide excellent solutions for high-end material processing in the aerospace field through technological innovation.

Technical Challenges

Machining high-strength materials like titanium alloys presents multiple technical difficulties:

- Extremely high material hardness leading to rapid tool wear

- Micron-level precision requirements

- Difficult temperature control during processing

- High tool costs

Innovative Solution

Our innovative cutting tool solution includes:

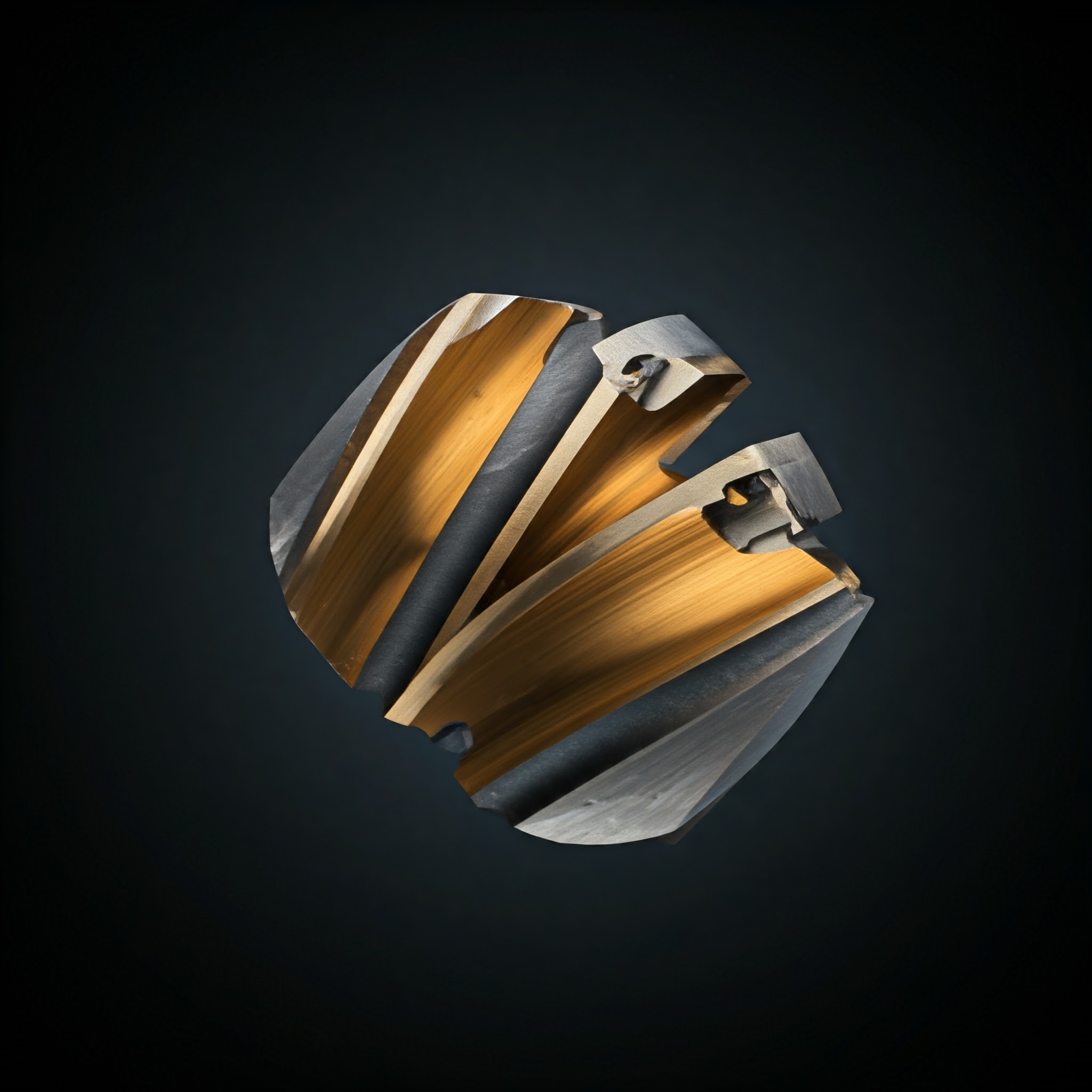

1. Nano-Composite Coating Technology

- Multi-layer nano-scale hard coating

- Significantly enhance tool wear resistance

- Reduce friction coefficient with processing materials

2. Precision Geometric Structure Design

- Optimize tool cutting angles

- Reduce cutting resistance

- Improve processing stability

3. Intelligent Cooling System

- Built-in efficient cooling channels

- Real-time temperature adjustment

- Prevent thermal deformation and material performance degradation

Project Results

Through these innovative technologies, we delivered significant benefits to our customers:

- Tool life increased by 65%

- Machining precision reached ±0.02mm

- Production efficiency improved by 40%

- Single tool usage cost reduced by 30%

Technical Indicators

| Performance Indicators | Traditional Solution | Innovative Solution | Improvement Ratio |

|---|---|---|---|

| Tool Life | 100 hours | 165 hours | 65% |

| Machining Precision | ±0.05mm | ±0.02mm | 60% |

| Production Efficiency | Standard Value | 1.4 times | 40% |