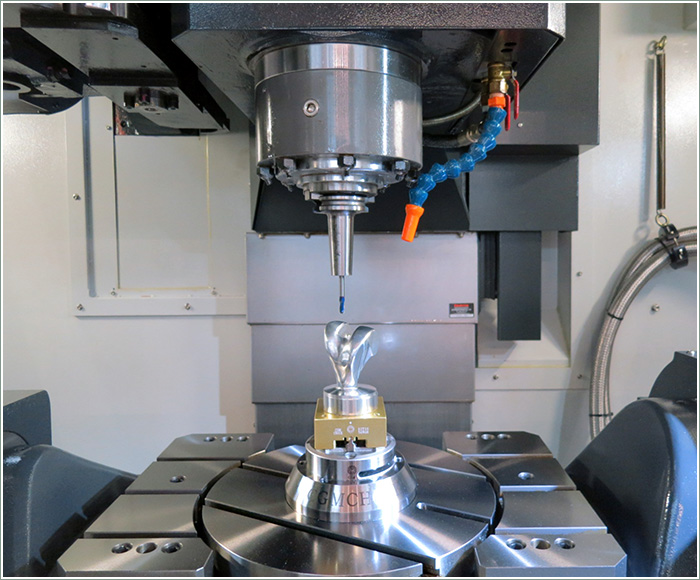

CNC milling machine

2020-02-20

CNC milling machine processing principle

CNC milling machine also processes through digital signal-driven milling machine

The milling machine moves the work piece in the XY plane, the Z axis is the tool spindle rotation, and milling is performed from top to bottom

It is a very economical way for a small or large number of productions to rotate the milling cutter through several cutting edges and move the work piece to the cutting machine.

Milling machine can fix the work piece. Rotary tools generally do 3D or 2D work pieces, and can accurately milling different shapes such as planes, curved surfaces, grooves, and gears.

The advantage of milling lies in its circular milling cutter, which has a high metal cutting rate and is also a more economical way.

It can cut in a very short time. Due to the different shape and mechanical application of the milling cutter, the milling machine can do all kinds of different milling work.

Including surface milling, curved milling, groove milling, gear milling, and cam milling, etc., a complex milling contour can be milled at one time by using a profile cutter, and the indexing head can mill a helical groove.

1. Milling machine types

The standard types of milling machines are universal milling machines, vertical milling machines and horizontal milling machines.

Vertical milling machine processing

It is named because the tool shaft is set upright.The movement of the worktable is the same as that of the ordinary milling machine, except that the milling cutter has no other movement except the rotary movement.

The rotary cutter head can rotate, and the rotary axis can be set on the vertical plane, any angle from vertical to horizontal.

The rotating shaft of this machine can move up and down a short distance in the mass axis, which is conducive to layer milling.

Some vertical milling machines have rotary attachments or rotary tables. Milling of troughs or continuous production of small-volume parts is possible. The cutting tools used in vertical milling machines are end mills.

Universal milling machine processing

The universal milling machine is the most versatile milling machine.In addition to its vertical, horizontal and vertical movement, the bed can be rotated 45 degrees left and right in the horizontal direction.

The milling cutter is mounted on the mandrel, and the mandrel has more than ten kinds of speeds, which are matched with the three-direction feed of the bed. Therefore, a variety of milling cutters and different conditions can be used to meet the needs of the work.

And the bed can rotate, so it can mill the spiral work and angled surface, so it is called universal milling machine.

Horizontal milling machine processing

This machine is mainly designed for milling large workpieces that need to mill a large amount of material, and to accurately reproduce surfaces and contours.Its working principle is to feed the rotating milling cutter at a suitable speed on a long table with only longitudinal movement.

2. Type of milling cutter

There are many types of milling cutters used in milling, which are used for different purposes, as described below:

Cylindrical milling cutter

Machining plane for horizontal milling machine, the teeth are distributed on the circumference of the milling cutter According to the tooth shape, it can be divided into straight teeth and spiral teeth. According to the number of teeth, it can be divided into coarse teeth and fine teeth. Spiral tooth coarse milling cutter has few teeth, high tooth strength, large chip space, and is suitable for rough machining; fine tooth milling cutter is suitable for finishing.

Face milling cutter

It is used for machining surface on vertical milling machines, face milling machines or gantry milling machines. There are cutter teeth on the end face and the circumference.Its structure has three types: integral type, inlay type and indexable type.

End mill

The cutter teeth are on the circumference and the end surface, and cannot be fed in the axial direction during work. When the end mill has end teeth passing through the center, it can feed axially usually used for machining grooves and steps

Three-sided edge milling cutter

It has cutter teeth on both sides and circumference for machining various groove and step angle cutters.There are two types of single-angle and double-angle milling cutters for milling grooves with a certain angle.

Sawblade cutter

It is used for machining deep grooves and cutting workpieces, and there are many cutter teeth on its circumference.In order to reduce friction during milling, there are auxiliary deflection angles of 15 ′ ~ 1 ° on both sides of the cutter teeth.