銑刀鍍層技術

2020-01-02

- 刀具鍍層

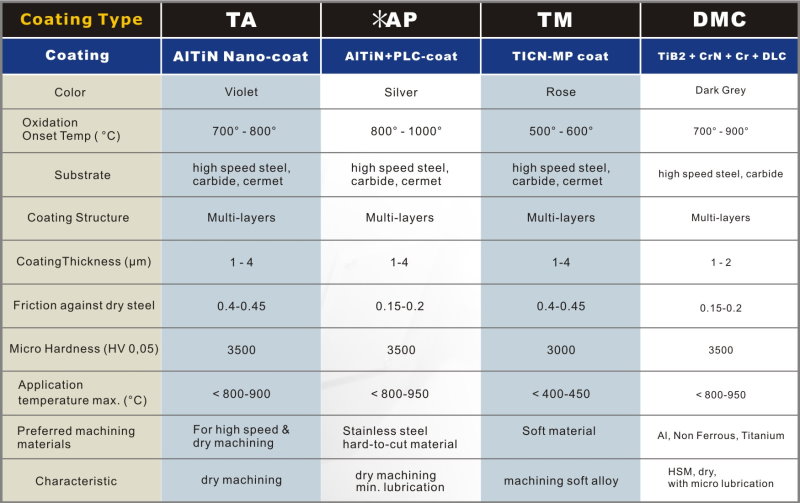

鍍層如同刀具之盔甲,具有強大的防護、耐酸、耐氧化抗磨耗等特性,可大幅增加刀具的壽命,使工件表面品質提昇,增進製造效率與品質優良率。 - 奈米氮化鋁鈦膜-Nano TiAlN

呈現黑紫色澤,適用於所有的加工切削,耐高溫與磨耗,延長工具壽命,排屑順暢..適用於乾切削及超硬材質,特別專用於高速切削。 - 類鑽膜-DiaCoat / DLC

類鑽碳的硬度高,使刀具能承受更高的加工溫度..類鑽碳膜的刀具適合用來加工鋁/鎂鋁合金、銅合金、鉛合金、陶瓷、碳化鎢、含碳材料(石墨、塑膠及複合材料、橡膠)等。 - 鑽石薄膜-CVD-Diamond

鑽石薄膜是以高溫高壓多晶成長,鑽石具優異物理特性及化學特性,硬度、熱導速度、低摩擦係數、良好電絕緣性等,用於切削石墨及碳纖維、陶瓷材料等難切削材料都有優異切削表現。 - AlTiN + PLC

呈現銀灰色澤,耐溫度超強,在不鏽鋼與難切削材料上的表現銳不可擋。 - 鎢鋼銑刀鍍層種類。

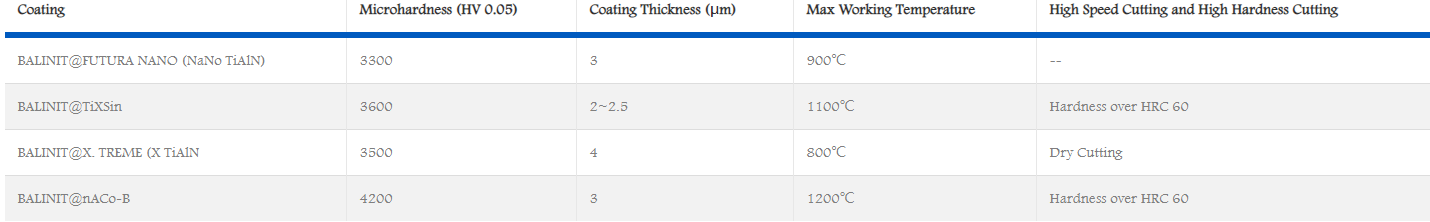

| Coating Layer |

TiN | TiCN | CrN | TiALN FUTURA |

TiALN FUTURA-NANO |

TiALN XTREME |

| Coating Material |

Titanium Nitride |

Titanium Carbon Nitride |

Chromiun Nitride |

Titanium Aluminum Nitride |

Titanium Aluminum Nitride |

Titanium Aluminum Nitride |

| Micro- hardness HV(HV0.05) |

2000 | 3000 | 1800 | 3000 | 3300 | 3500 |

| Coefficient Against Steel(Dry) |

0.4 | 0.4 | 0.5 | 0.4 | 0.3~0.35 | 0.4 |

| Process Temperature |

450 ℃ 840 ℉ |

450 ℃ 840 ℉ |

400℃ 750 ℉ |

450 ℃ 840 ℉ |

450 ℃ 840℉ |

450 ℃ 840 ℉ |

| Max. Working Temperature |

600 ℃ 1100 ℉ |

400 ℃ 750 ℉ |

700℃ 1300 ℉ |

800 ℃ 1470 ℉ |

900 ℃ 1650℉ |

800 ℃ 1470 ℉ |

| Coating Color |

Gold | Blue- Gray |

Silver- Gray |

Violet- Gray |

Violet- Gray |

Violet- Gray |

| Key Characteristics |

Good general purpose | High hardness, goodwear resistance enhanced toughness |

Good adhesion, good corrosion and oxidation resistance | Good adhesion, good corrosion and oxidation resistance |

Excellent oxidation resistance |

Excellent oxidation resistance |

| Primary Applications |

Machining of iron-based materials Metal forming Plastic molding |

For machining difficult-to machine steel alloys and high speed cutting where moderate temp are generated at the cutting edge Metal forming |

Machining copper Metal forming Plastic molding |

A multilayer coating designed for a wide range of carbide, cermet and high speed steel tooling Excellent for machining cast iron,stainless steel,nickel-based high temperature alloys and titanium alloys Designed for high speed and semi-dry or dry machining operations |

The cha-racteristics of FUTURA are maintained and even improved in excellent adhesion, higher hardness, lower residual compressive stress Excellent for machining cast iron,stainless steel,nickel-based high temperature alloysand titanium alloys Designed for high speed andsemi-dry or dry machining operations |

A specialized coating designed specifically for use on carbide end mills for the machining of hardened steel workpieces Designed for high speed and semi-dry or dry machining operations |