鎢鋼等級

2020-01-02

鎢鋼是什麼?

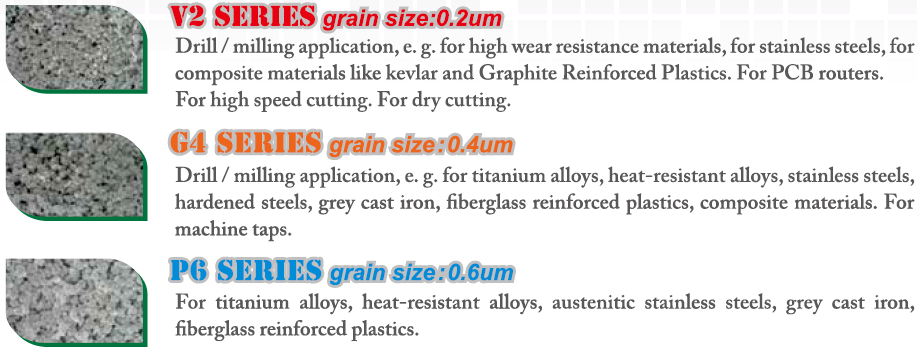

鎢鋼是碳化鎢的俗稱,英文是 Tungsten Carbide ,當然除了碳跟鎢之外還加了鈷以及其他的合金材料以增加他的機械性能,鎢鋼的硬度很高,有分很多不同等級,常用來做為切削刀具銑刀常用的材料。鎢鋼一般是用粉末燒結的方式製成,將鎢粉末、碳黑粉末、用作結合劑的鈷金屬粉末以及其他合金粉末混合後,施以高壓,在高溫下燒結而成。鎢鋼的機械性質主要由兩個部分影響,第一個部分是鈷的含量..含量越高硬度越低但是韌性較好,個是粉末的粒徑,粒徑越小越耐磨,但是成本較高。

> 立即點我【看更多銑刀產品】

鎢鋼等級

.png)

鎢鋼材質

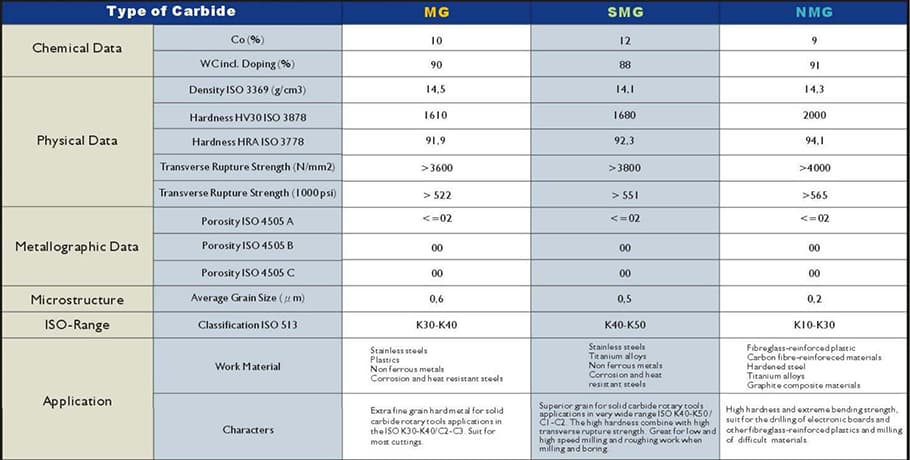

| 鎢 鋼 材 質 分 析 表 | |||||

| 鎢鋼種類 | MG 超微粒 |

Super MG 極細超微粒 |

NMG 奈米超微粒 |

EMG 高鈷超微粒 |

|

|

|

|

|

||

| 化學成分 | Co(%) | 10 | 12 | 9 | 13 |

| WC incl. Doping (%) | 90 | 88 | 91 | 87 | |

| 物理特性 | Density ISO 3369 (g/cm3) | 14.5 | 14.1 | 14.3 | 13.9 |

| Hardness HV30 ISO 3878 | 1610 | 1680 | 2000 | 1700 | |

| Hardness HRA ISO 3778 | 91.9 | 92.3 | 94.1 | 92.4 | |

| Transverse Rupture Strength (N/mm2) | >3600 | >3800 | >4000 | >3900 | |

| Transverse Rupture Strength (1000 psi) | >522 | >551 | >565 | >565 | |

| 顯微數據 | Porosity ISO 4505 A | <=2 | <=2 | <=2 | <=2 |

| Porosity ISO 4505 B | 00 | 00 | 00 | 00 | |

| Porosity ISO 4505 C | 00 | 00 | 00 | 00 | |

| 微構造 | Average Grain Size (μm) | 0.6 | 0.5 | 0.2 | 0.5 |

| ISO標準 | Classification ISO 513 | K30 ~ K40 | K40 ~ K50 | K10 ~ K30 | K40 ~ K50 |

| 應用範圍 | Work Material | Stainless steels Titanium alloys Plastics Non ferrous metals Corrosion and heat resistant steels | Stainless steels Titanium alloys Non ferrous metals Corrosion and heat resistant steels | Fibreglass-reinforced plastic Grey cast iron Carbon fibre-reinforeced materials Hardened steel Graphite composite materials Aluminium alloys | Corrosion and heat resistant stells Stainless steels Titanium alloys Non ferrous matals |

| Characters | Extra fine grain hard metal for solid carbide rotary tools applications in the ISO K30-K40/C2-C3. Suit for most cuttings. | Superior grain for solid carbide rotary tools applications in very wide range ISO K40 -K50 / C1-C2. Great for low and high speed milling and roughing work when milling and boring. | High hardness and extreme bending strength, suit for the drilling of electronic boards and other fibreglass-reinforced plastics and milling of difficult materials. | Murakami-Etching | |