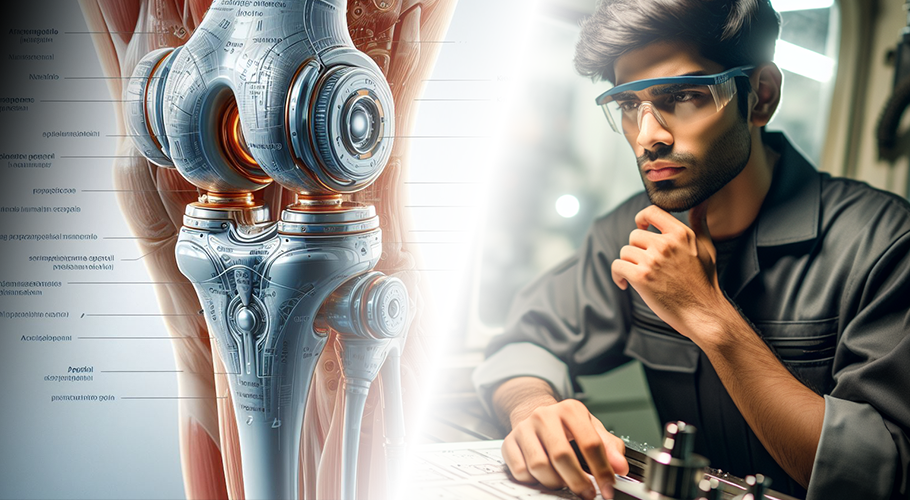

CNC Machining of Medical Artificial Knee Joints - Challenges Faced When Cutting Difficult-to-Machine Materials with Tungsten Carbide End Mills

2024-04-09

The medical device industry is a highly precise and strictly regulated field, and medical artificial knee joints are undoubtedly one of the most complex products. As an important replacement for natural joints, artificial knee joints need to meet strict functional and material requirements, which also brings many challenges to CNC machining.

Firstly, the main materials of medical artificial knee joints are usually cobalt-chromium alloys or ceramics, which are difficult-to-machine. These materials often have high hardness, strong wear resistance, and low toughness, making the cutting process more difficult. The end mills are prone to rapid wear, and the workpiece surface roughness is relatively high, requiring special tool selection and process parameters.

Secondly, the structure of artificial knee joints is complex, often including curved surfaces, holes, and other geometric features, with high requirements for machining accuracy. CNC machinists need to carefully design the workholding scheme to ensure the stability of the workpiece, while also considering the control of workpiece deformation. At the same time, minute dimensional deviations may affect the joint's mobility and service life, so measurement and quality control during the machining process are crucial.

Furthermore, as implantable medical devices, the manufacturing process of artificial knee joints must strictly follow hygiene and harmlessness requirements. The CNC machining workshop needs to establish a dust-free operating environment and adopt special lubrication and cleaning methods to ensure the machined surface is free of any contamination.

Finally, CNC machinists also need to have extensive knowledge and experience in medical device manufacturing. They must have a deep understanding of the design principles and usage requirements of artificial knee joints, in order to select appropriate machining solutions and continuously optimize the process to ensure product quality and reliability.

In summary, using CNC machine tools to machine difficult-to-machine materials for medical artificial knee joints places high demands on process capabilities and professional expertise. Only CNC machinists with comprehensive technical skills can efficiently complete this challenging machining task while meeting strict standards.