The Invisible Heroes Shaping Precision in the Medical Industry

2024-02-15

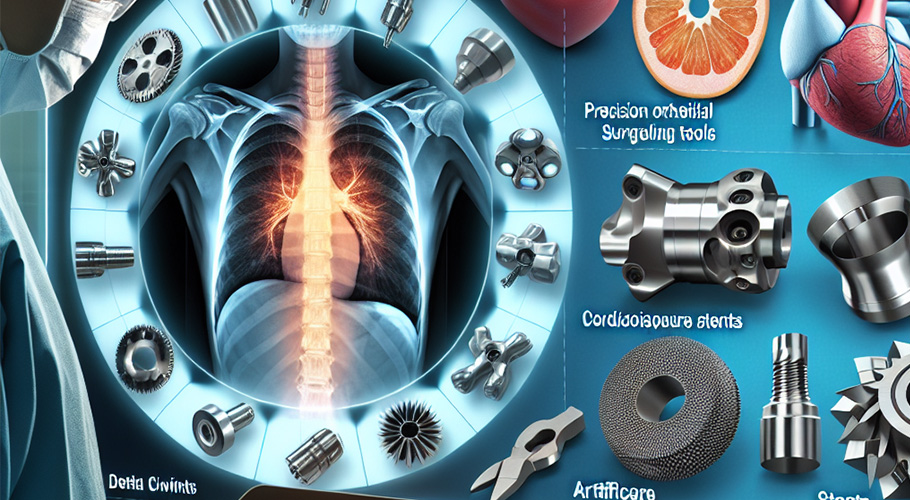

The progress of the medical industry is intimately linked with the development of precision tools, among which the tungsten carbide milling cutter plays a pivotal role. These cutting tools, composed primarily of a durable carbide, are treasured assets in modern medical device manufacturing because of their exceptional hardness and outstanding wear resistance.

For orthopedic surgery, precision cutting is indispensable. With their delicate yet robust cutting edges, tungsten carbide milling cutters offer surgeons an ideal tool for cutting bone or removing old implants. Compared to traditional steel tools, their use lessens the challenges encountered during surgeries while increasing accuracy and safety.

Beyond orthopedic surgery, tungsten carbide milling cutters are essential for creating medical implants and devices. They are employed in fabricating cardiovascular stents, prosthetic joints, dental implants, and other highly precise sub-micron level devices. Owing to the hard properties of tungsten carbide, material deformation and wear can be significantly reduced during these precision machining tasks.

In the field of dentistry, tungsten carbide milling cutters also demonstrate incomparable value. The miniaturization of dental implants and restorative components necessitates tools with high rigidity and astonishing precision—the very characteristics of tungsten carbide cutters, making them the preferred choice for dental applications.

Furthermore, with the rise of personalized medicine and tailored treatments, 3D printing technology has started to be widely applied in the production of medical devices and implants. Tungsten carbide milling cutters are key during the post-processing stage of 3D printing, removing excess materials and smoothing surfaces to ensure the optimal performance of medical devices.

In summary, the high hardness, wear resistance, chemical stability, and excellent heat dissipation capabilities of tungsten carbide milling cutters make them a driving force in the continuous push for innovation in the medical industry. Whether improving surgical tools, fabricating implants, or enhancing the quality of personalized medical equipment, they have shown their irreplaceable worth. As technology advances further, we anticipate them bringing more innovation and breakthroughs in the medical field.

For orthopedic surgery, precision cutting is indispensable. With their delicate yet robust cutting edges, tungsten carbide milling cutters offer surgeons an ideal tool for cutting bone or removing old implants. Compared to traditional steel tools, their use lessens the challenges encountered during surgeries while increasing accuracy and safety.

Beyond orthopedic surgery, tungsten carbide milling cutters are essential for creating medical implants and devices. They are employed in fabricating cardiovascular stents, prosthetic joints, dental implants, and other highly precise sub-micron level devices. Owing to the hard properties of tungsten carbide, material deformation and wear can be significantly reduced during these precision machining tasks.

In the field of dentistry, tungsten carbide milling cutters also demonstrate incomparable value. The miniaturization of dental implants and restorative components necessitates tools with high rigidity and astonishing precision—the very characteristics of tungsten carbide cutters, making them the preferred choice for dental applications.

Furthermore, with the rise of personalized medicine and tailored treatments, 3D printing technology has started to be widely applied in the production of medical devices and implants. Tungsten carbide milling cutters are key during the post-processing stage of 3D printing, removing excess materials and smoothing surfaces to ensure the optimal performance of medical devices.

In summary, the high hardness, wear resistance, chemical stability, and excellent heat dissipation capabilities of tungsten carbide milling cutters make them a driving force in the continuous push for innovation in the medical industry. Whether improving surgical tools, fabricating implants, or enhancing the quality of personalized medical equipment, they have shown their irreplaceable worth. As technology advances further, we anticipate them bringing more innovation and breakthroughs in the medical field.